#10 Window Installation & Considerations

The first notable step in the retrofit was to have the windows replaced... there's a lot we didn't know!

Finalising Quotes

The initial quotes we received for the window installation were based on David’s documentation, however, we needed the window supplier (Binq) to come measure up to finalise their costs for supply and installation, and to get quotes for some additional items. Due to the myriad of lockdowns in 2021 this process took much longer than we would’ve liked. Specific additional items we needed quotes for included providing retractable fly screens for our sliding doors (Binq supplied and installed these Brio screens), and for painting the windows. As we wanted the windows painted, and not stained, we had to find a painter to do this once the windows were installed. The windows came primed and only gave us a few days post-installation to get them painted to maintain their warranty. We wanted to keep the look of the sash windows as well, so opted for glazing bars that stick to the glass, making it look like two separate windows.

Understanding Window Installation

Removing and installing a window sounds pretty straightforward but as we started finalising quotes and talking in more detail about the installation process, the enormity of the task became more apparent (although still not fully apparent).

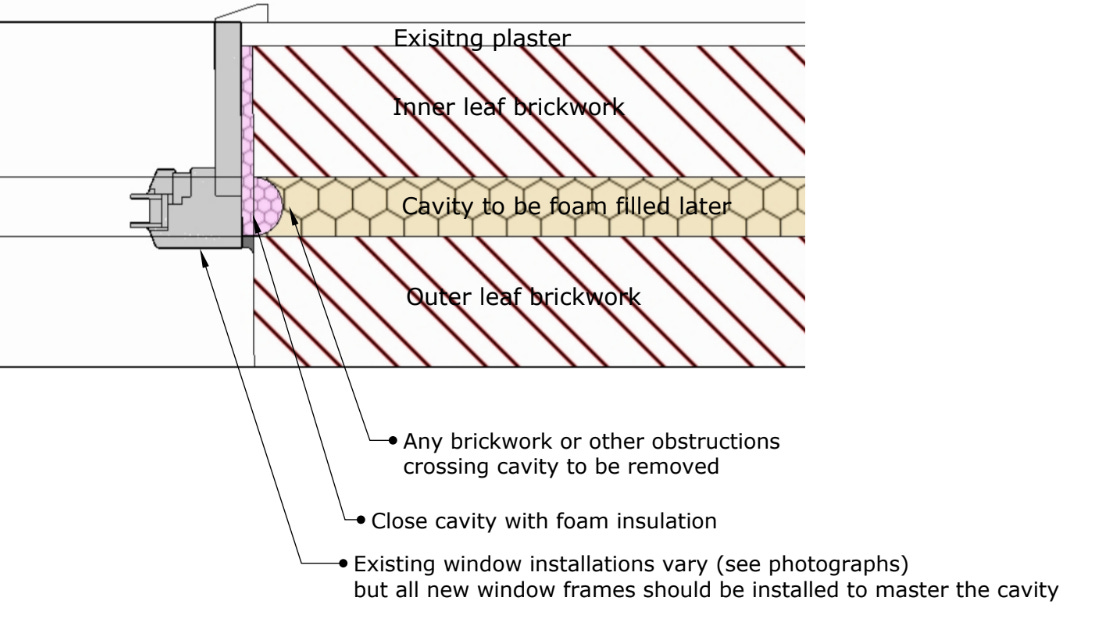

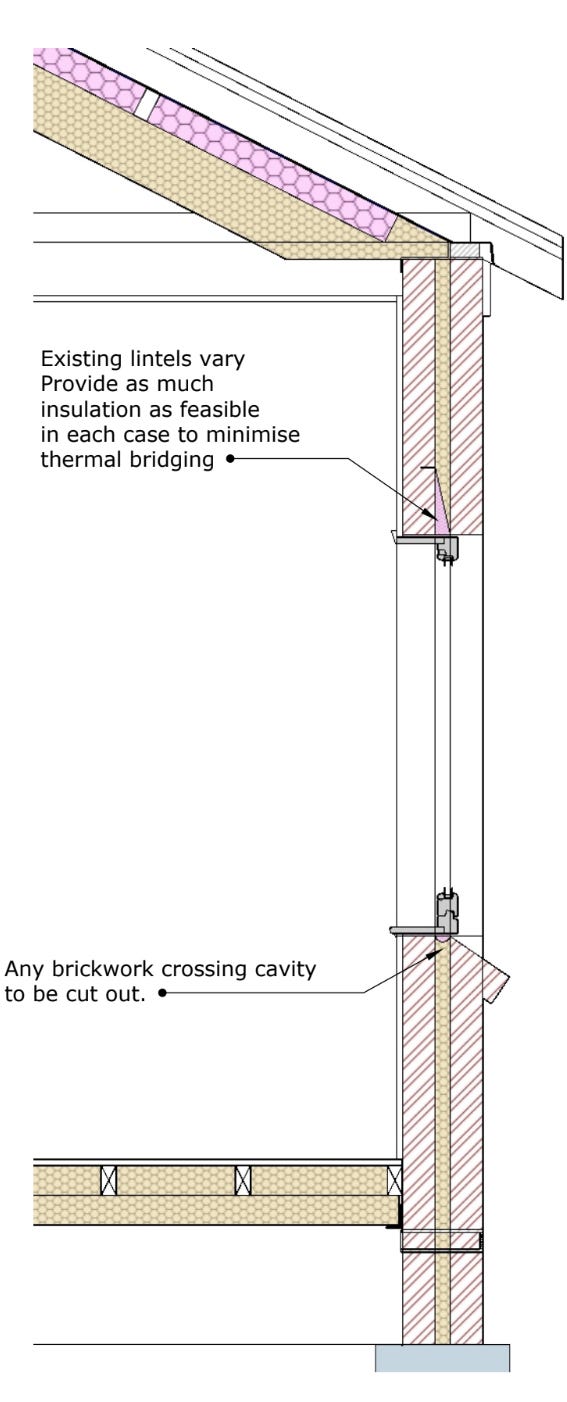

During the measure up from Binq we were warned/advised that removing windows in double brick homes is a bit of a lottery - you don’t really know what you’re going to find once you take the windows out. This was concerning as not only did we need the windows to be replaced, but we needed to ensure the windows were installed in-line with the wall cavity for the continuous airtight barrier, that there would be no thermal bridges, and that there was appropriate weatherproofing until the wall cavities were filled. We also needed the architraves removed and reinstated. Further we did also want to maintain our lead light windows, which we were trying to design into the Binq frames, but between lockdowns and everything else we decided to install the Binq windows as is and figure out retrofitting the lead lights back in at a later date.

At this point there seemed to be a lot of interdependencies in the installation process; removing the windows cautiously so we could resell them, removing any thermal bridges without compromising the structural integrity of the walls, making the top of the windows exposed to the cavity weatherproof, removing and reinstating the architraves, and painting!!! Additionally, until we started removing windows we wouldn’t know how big of an issue, if at all, some of these things would be! As we weren’t planning on moving out for more than a few days, we couldn’t leave windows uninstalled whilst we coordinated/figured things out!

With all of these moving parts we considered engaging a builder to oversee everything. We spoke with David and got a few recommendations, however, due to the relatively small nature of our works, and the frantic and frenzied state of the construction industry we couldn’t find anyone willing to take this on. So we pressed forward!

The Install

We opted for Binq to do both the window supply and installation. It took a few reschedules to get started due to the lockdown restrictions but in November 2021 we were off and running. Finally reaching the day the windows were delivered was pretty exciting, but we also had some apprehension about what we were going to find as we started removing the old windows. The install was scheduled to take 3 days.

Most of the old windows came out fairly easily, with the exception of some of the sash windows that had to come out in a few pieces. The large glass doors came out well, but there was a bit of water damage due to the way they had previously been installed which had resulted in water pooling against the doors.

In terms of maintaining the continuous insulation layer and eliminating thermal bridges though, we started to run into several challenges. Notably:

Bricks installed across the cavity bridging the inner and outer leaf at the window jambs.

Steel lintels above the windows.

Sill bricks leaving little or no cavity.

Mortar bridging cavities.

Once the trims were removed, the sash window openings were significantly larger than the new windows.

The bricks bridging the inner and outer leaf thankfully only occurred on one window, and the installer was willing to accommodate removing these. We were told by the installer that there wasn't much we could do with the steel lintels and sill bricks bridging the cavity short of redoing the external sill. As this wasn't something we wanted to contemplate at this stage, they unfortunately had to stay to deal with at a later date. A blow for our Enerphit ambitions, but necessary given we needed windows in our house!

The gaps around the old sash windows were fitted with timber supports, and a spray foam used to fill any uneven gaps. The application of spray foam wasn't particularly robust, so we ended up using Tescon Extora tape (partly because we had some handy) around the windows. This meant we had to move pretty quickly to get everything taped before the trims went back on the windows.

New window that replaced an old sash window, with additional timbers for support.

Some particular challenges/lessons from the installation:

Several windows were measured incorrectly. To Binq’s credit they fixed all of these at no additional cost.

A window was made as a single unit but was replacing two separate windows. To remedy this, it involved removing a structural beam and reinforcing above the window. Whilst this took a lot longer to install, again Binq came to the party on this. It was good we had a single point of contact for supply and install.

The install took longer than estimated. We knew from the earlier advice that there would be plenty of unknowns until the old windows were removed, so it wasn't like we were in blindsided by it taking a bit longer.

Coordinating painters around the installation, dust created from the install, weather and delays wasn't easy or cheap. If we did things again, we'd seriously consider having them painted in the factory if that were an option.

We definitely underestimated how intrusive this was going to be. We stayed with family whilst the works went on, but the amount of dust it created, and general building waste was a bit more than we had anticipated - purely our naivety. There was lots of post-window installation cleaning to do!

Highlights:

Awesome lift and slide window in the kitchen looking out onto the back garden! This was one of the first lift and slide windows Binq had made, it's very handy.

The Brio collapsing fly screens on the lift and slide doors were a hit. We thought we were going to miss having concertina doors, but having lift and slide doors at opposite ends of the house and Brio fly screens means we can still really open the place up when we want to.

No more drafts whilst sitting next to a window.

Condensation forming on the outside of the windows now (see below), and not the inside!!

Note on the delayed post: Yes, November 2021 is a long time ago, I'm very behind writing. We've made a lot of progress since then that I'll endeavour to update more promptly!!

Thank you Kieran for taking the time to record your experience. Looks like we’ll be following you down the Enerphit track and you paving the way will help us in the future.